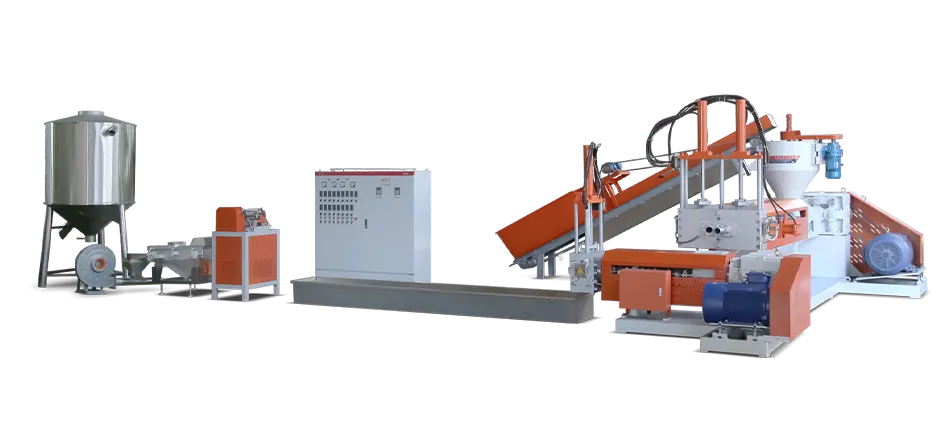

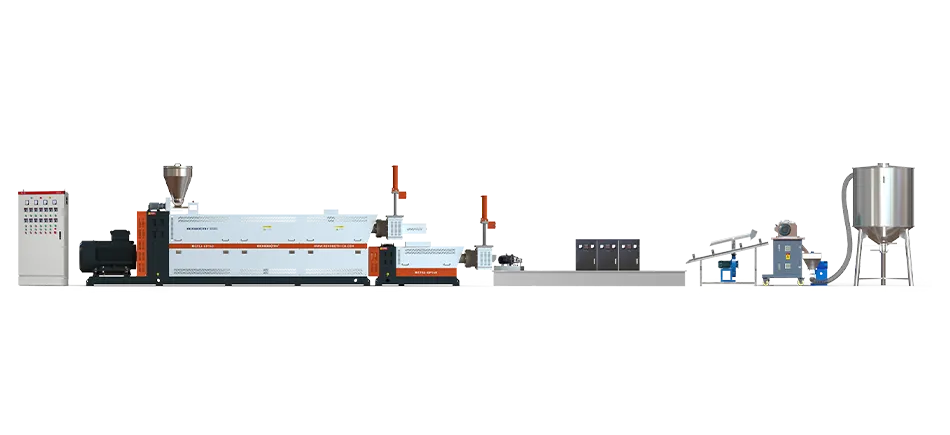

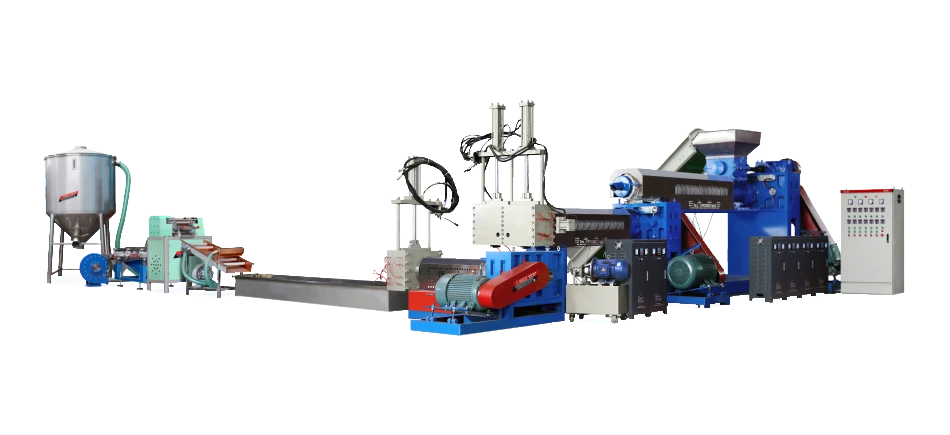

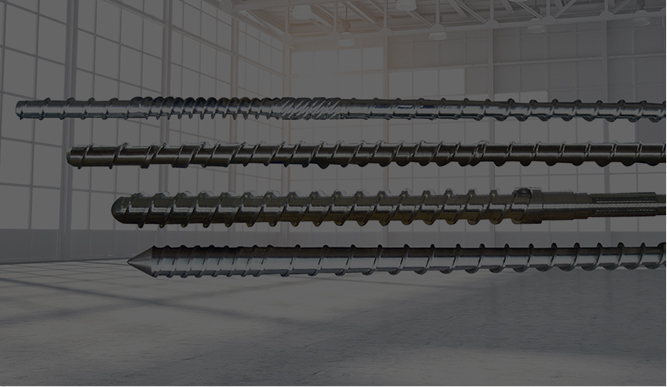

Our plastic pelletizers feature unique screw designs and various configurations. Modelsinclude single-screw, conical twin-screw, and parallel twin-screw models. These pelletizersare suitable for recycling and color-mixing most common waste plastics, including PP, PE, PS.ABS, PA, PVC, PC, POM, EVA, LCP, PET, and PMMA.

Download

Manual

Download

Manual Video

Video

Connect:

Connect: