If you're searching for an efficient solution to recycle PET plastic waste into high-quality, food-contact grade pellets for bottle-to-bottle recycling, the REHOBOTH PET Plastic Recycling Pelletizer is the answer. This advanced system offers direct pelletizing of washed flakes with precise IV control, making it ideal for sustainable plastic waste management operations.

How the PET Plastic Recycling Pelletizer Works

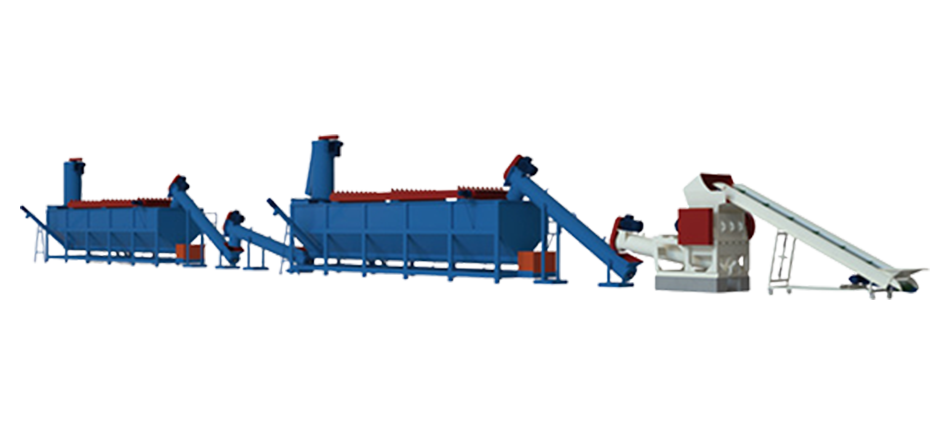

The PET Plastic Recycling Pelletizer operates through a multi-stage process that transforms washed plastic flakes into uniform pellets ready for new product manufacturing. The system consists of several key components working together seamlessly:

- Conveyor System: Transports washed plastic flakes to the main machine

- Main Machine: First stage processing unit that begins the pelletizing process

- Second Stage: Refines the plastic material for better consistency

- Third Stage: Final processing stage for optimal pellet quality

- Water Tank: Cools the pellets during production

- Blow Fan: Dries the pellets after cooling

- Cutter: Precisely cuts the material into uniform pellets

- Silo: Stores the finished pellets

- Electric Box: Controls and monitors the entire system operation

This comprehensive setup ensures that every step of the recycling process is optimized for efficiency and quality output.

Key Features of the REHOBOTH PET Plastic Recycling Pelletizer

The REHOBOTH PET Plastic Recycling Pelletizer stands out from competitors with its impressive features designed for industrial-scale recycling operations:

- Direct Pelletizing Technology: Processes washed flakes directly without additional pre-treatment steps

- Precise IV Control: Maintains consistent intrinsic viscosity for high-quality end products

- Food-Contact Grade Production: Creates pellets suitable for bottle-to-bottle recycling applications

- Multi-Material Compatibility: Handles various plastics including ABS, PE, PA, PP, PS, PP-R, ABS + PC, and POM

- Energy-Efficient Design: Optimized processing that reduces operational costs

- Low Maintenance Requirements: Durable components designed for continuous industrial use

Applications of the PET Plastic Recycling Pelletizer

This versatile machine finds applications in numerous industries requiring sustainable plastic waste management solutions:

- Bottle-to-Bottle Recycling: Produces food-contact grade pellets for new beverage containers

- Packaging Industry: Creates raw material for new plastic packaging products

- Textile Manufacturing: Generates fibers for carpet and clothing production

- Automotive Sector: Provides material for interior components and parts

- Construction Industry: Supplies pellets for various plastic construction materials

Why Choose REHOBOTH for Your Plastic Recycling Needs

When investing in a PET Plastic Recycling Pelletizer, choosing REHOBOTH offers distinct advantages:

- Engineering Excellence: Decades of experience in plastic machinery manufacturing

- Global Support Network: Comprehensive service and support for international operations

- Customization Options: Solutions tailored to specific recycling requirements

- Proven Reliability: Systems operating successfully in diverse global environments

- Future-Ready Technology: Continuous innovation in recycling solutions

Real-World Success with REHOBOTH PET Plastic Recycling Pelletizer

Many businesses have experienced significant benefits after implementing the REHOBOTH PET Plastic Recycling Pelletizer in their operations:

"Our bottle-to-bottle recycling operation saw a 35% increase in production efficiency after switching to the REHOBOTH system. The precise IV control has allowed us to maintain consistent quality for our food-contact applications." - African Recycling Facility Manager

"The multi-material compatibility of the REHOBOTH pelletizer has enabled us to expand our recycling capabilities beyond PET to include other plastics, increasing our revenue streams while reducing waste." - European Packaging Manufacturer

Get Started with Your PET Plastic Recycling Solution

Ready to transform your plastic waste management operations with the REHOBOTH PET Plastic Recycling Pelletizer? Whether you need a standard system or have special customization requirements, our team is ready to help.

GET A QUOTE today by contacting us at +86 15067777992 or emailing 15067777992@rehoboth-machine.com. Our experts will work with you to determine the best solution for your specific recycling needs.

For more information about our complete line of plastic recycling solutions, visit our product pages:

- Rigid Plastic Recycling Pelletizer

- Film Plastic Recycling Solutions

- PET Plastic Recycling and Washing Line

Join the plastic recycling revolution with REHOBOTH and turn your plastic waste into valuable resources for a sustainable future.

Download

Manual

Download

Manual Video

Video

Connect:

Connect: