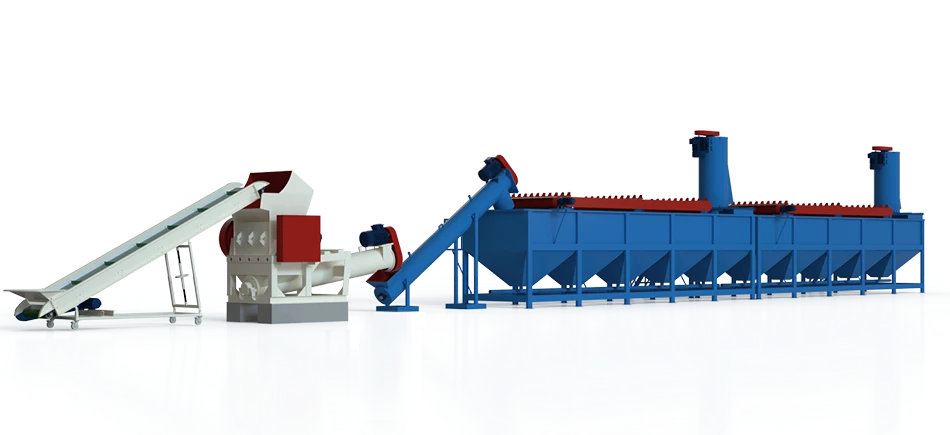

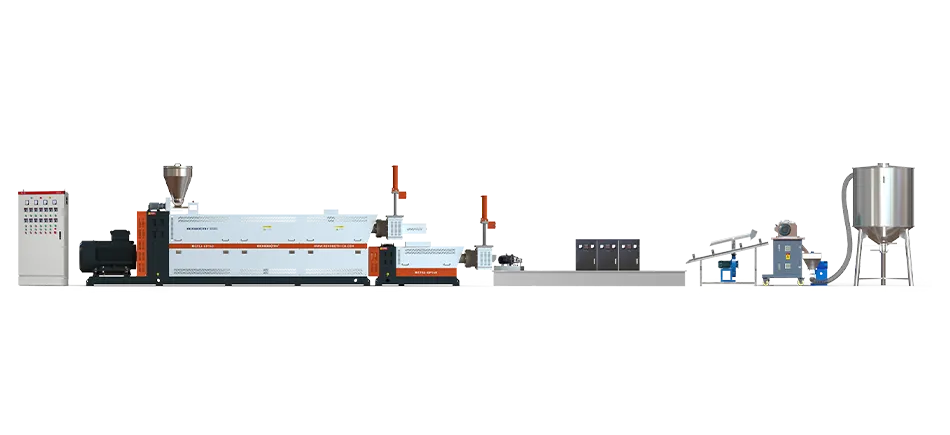

Through deep cleaning and closed-loop water circulation, it drastically cuts water and disposal costs while enabling recycled flakes to enter high-end fiber and packaging markets.

Dirty injection-molded parts

Dirty plastic bags

Dirty plastic film

Dirty mineral water bottles

Download

Manual

Download

Manual Video

Video

Connect:

Connect: