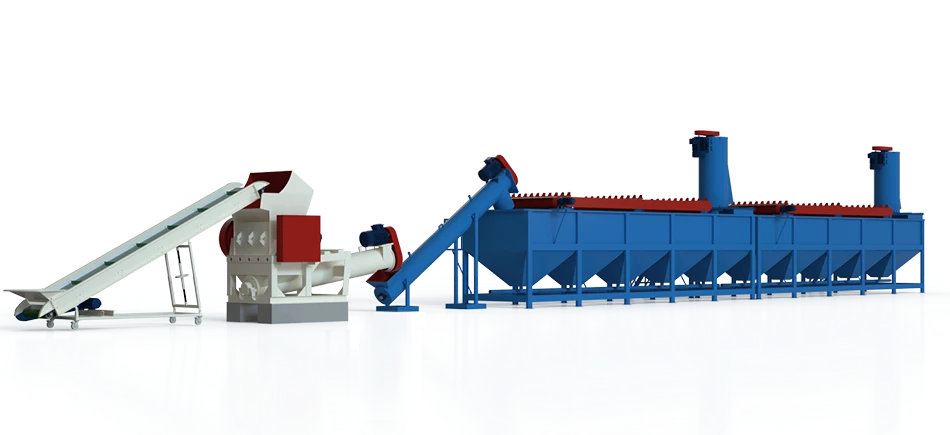

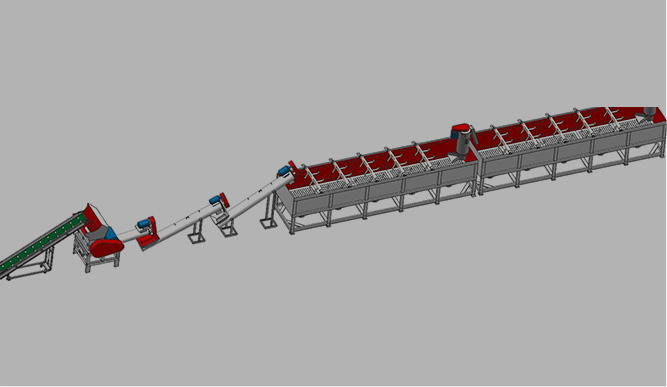

The REHOBOTH cleaning line is not merely a simple decontamination step, but a self-sustaining micro-ecosystem operating within your facility. We not only clean plastics but also purify every byproduct generated during the cleaning process, transforming the cost center of “pollution” into your environmental competitiveness and compliance assurance.

Download

Manual

Download

Manual Video

Video

Connect:

Connect: