Implement a cleaning and recycling line comprising sorting, crushing, de-metallization, hot and cold washing, high-efficiency friction washing, and drying modules.

Energy Savings in the Drive System

Most systems utilize variable frequency drives (VFDs) to conserve energy by reducing excess motor power consumption. For instance, if a motor's actual power output is rated at 50Hz but production only requires 30Hz, the unused capacity results in wasted energy. VFDs adjust the motor's power output to achieve energy savings.

Heating Section Energy Efficiency

Heating section energy savings are primarily achieved through electromagnetic heaters, offering energy efficiency gains of approximately 30%-70% compared to traditional resistance heating coils.

| Name | Specification | |

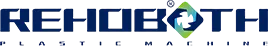

| Crusher | Model | 600 |

| Motor | 18.5kw, 7.5KW | |

| Speed | 500rpm | |

| Rotary blade | 6 | |

| Fixed blade | 4 | |

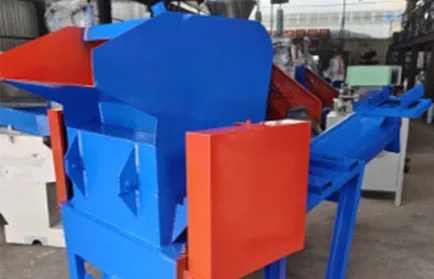

| Screw length | 2.5m | |

| Screw Washer | Length | 3m |

| Diameter | 300mm | |

| Motor | 7.5KW | |

| Washing Tank | Length | 6000mm |

| Width | 1200mm | |

| Pusher | 3pcs | |

| Motor | 1.5kw=1pcs | |

| Material Lifting Dewatering Machine | Model | 550 |

| Diameter | 550mm | |

| Length | 2m | |

| Motor | 7.5KW | |

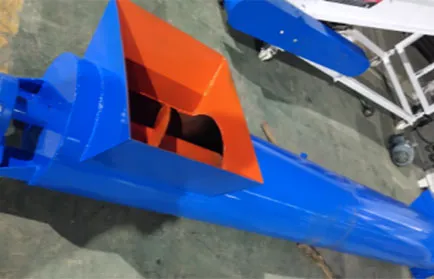

| Horizontal Dryer | Motor | 18.5KW |

| Diameter | 600mm | |

| Speed | 1450r/min | |

| Electric Box | Brand | CHINT |

Crusher

Screw Washer

Washing Tank

Material Lifting Dewatering Machine

Horizontal Dryer

Electric Box

Through deep cleaning and closed-loop water circulation, it drastically cuts water and disposal costs while enabling recycled flakes to enter high-end fiber and packaging markets.