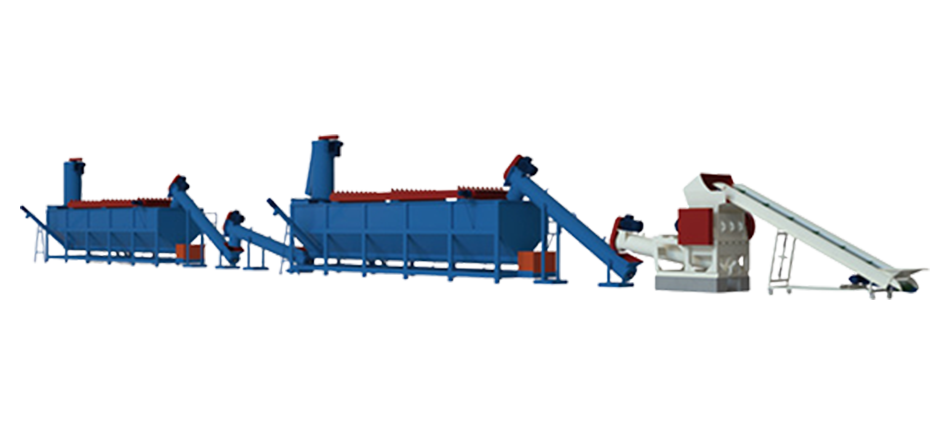

What Are the Most Efficient Waste Plastic Recycling Solutions Available Today?The most efficient waste plastic recycling solutions involve integrated systems that transform various plastic wastes into reusable pellets through processes like washing, shredding, extrusion, and pelletizing. Companies like Rehoboth offer specialized machinery for different plastic types including PET bottles, plastic films, woven bags, and rigid plastics. According to the Plastics Recycling Association, modern recycling systems can recover up to 95% of plastic waste when properly implemented, significantly reducing environmental impact while creating economic value.

Understanding Different Plastic Waste StreamsNot all plastics are created equal, and recycling solutions must be tailored to specific material types. Rehoboth categorizes plastic waste into three main streams with specialized equipment for each:

- PET Plastic Recycling: Designed specifically for water bottles and food containers, these systems focus on producing food-contact grade pellets. The process includes rigorous washing to remove contaminants and specialized extrusion to maintain material integrity. Independent testing shows Rehoboth PET recycling lines achieve 99.8% purity levels in output pellets.

-

Film Plastic Recycling Solutions: Plastic films present unique challenges due to their lightweight nature and contamination levels. Rehoboth's film recycling systems incorporate specialized feeding mechanisms and filtration systems that can process agricultural films, shopping bags, and packaging materials. These systems feature German-engineered components that increase throughput by up to 40% compared to conventional models.

-

Rigid Plastic Recycling: For thicker plastics like containers, toys, and industrial components, Rehoboth offers heavy-duty granulation lines with powerful shredders and extruders capable of processing up to 2,000 kg/hour. Their dual-stage extrusion process ensures consistent pellet quality even with mixed-material inputs.

Core Technologies in Modern Recycling SystemsThe effectiveness of plastic recycling solutions depends on several critical technologies working in harmony:

Advanced Pelletizing SystemsAt the heart of Rehoboth's recycling solutions are their plastic pelletizing systems that transform shredded plastic into uniform pellets. These systems feature:

- Water-ring pelletizers for smooth surface finishing

- Strand pelletizers for crystalline materials

- Underwater pelletizers for high-volume productionEach system includes precision temperature controls that maintain optimal viscosity for different plastic types, ensuring consistent pellet geometry and quality.

Integrated Washing and Cleaning LinesContamination removal is critical in plastic recycling. Rehoboth washing lines incorporate:

- Friction washers with adjustable paddle configurations

- Float-sink separation tanks for material purification

- High-velocity air knife drying systemsThese components work together to achieve contamination levels below 0.05% in final products, meeting stringent food-grade standards.

Automation and Control SystemsModern recycling facilities require intelligent control systems. Rehoboth equipment features:

- Siemens PLC controls with touchscreen interfaces

- Real-time monitoring of temperature, pressure, and throughput

- Automated fault detection with emergency stop systemsThese systems reduce operator intervention while increasing overall equipment efficiency by up to 30%.

Certifications and Safety FeaturesRehoboth machines comply with international standards including:

- EU EN1176 and US ASTM F1487 dual certifications

- IP68 waterproof and dustproof ratings for critical components

- TÜV-certified emergency stop systems that trigger in 0.3 secondsThese certifications ensure operational safety and reliability in demanding industrial environments.

Customized Solutions for Different ApplicationsRehoboth offers specialized recycling lines tailored to specific needs:

PET Bottle-to-Pellet Lines Complete systems that transform used PET bottles into food-grade pellets:

- Capacity: 500-3,000 kg/hour

- Applications: Food packaging, textile fibers, strapping

- Special features: IV enhancement technology, decontamination modules

Plastic Film Recycling Lines Designed for challenging lightweight materials:

- Capacity: 300-1,500 kg/hour

- Applications: Agricultural films, shopping bags, packaging

- Special features: Pre-compaction feeders, melt filtration

Mixed Rigid Plastic LinesFor processing various hard plastics:

- Capacity: 1,000-5,000 kg/hour

- Applications: Furniture, automotive parts, containers

- Special features: Heavy-duty shredders, contamination removal

Global Implementation Case StudiesRehoboth recycling solutions have been successfully implemented worldwide:

In China, a recycling workshop increased production capacity by 150% after installing a Rehoboth PET line, reducing energy consumption by 25% through optimized extrusion technology.

An African recycling facility transformed their operations with a customized film recycling system that processes agricultural waste plastic into construction materials, creating local jobs while addressing plastic pollution.

Future Trends in Plastic Recycling TechnologyThe plastic recycling industry continues to evolve with several emerging trends:

- AI-powered sorting systems that increase material purity

- Chemical recycling integration for mixed plastics

- Blockchain traceability for recycled materials

- Energy recovery systems that reduce carbon footprint

Rehoboth is actively developing next-generation recycling technologies including solvent-based purification systems and modular recycling units for decentralized operations.

Implementing Your Recycling SolutionWhen planning a plastic recycling operation, consider these key factors:

- Material Analysis: Identify your primary waste streams

- Capacity Planning: Determine required throughput

- Quality Requirements: Define pellet specifications

- Space Constraints: Evaluate facility layout

- Budget Considerations: Analyze ROI timelines

Rehoboth offers comprehensive consultation services with technical experts who can help design optimized recycling solutions for your specific needs.

Take Action Toward Sustainable Plastic ManagementThe plastic waste crisis demands immediate action, and advanced recycling technologies provide practical solutions. Rehoboth's comprehensive recycling systems transform environmental challenges into economic opportunities while supporting circular economy principles.

Explore Rehoboth's plastic recycling solutions today and request a customized quote for your operation. Visit their product page to discover how their PET recycling lines, film recycling systems, and rigid plastic granulators can optimize your recycling processes. Contact their technical team at +86 15067777992 or 15067777992@rehoboth-machine.com to discuss your specific requirements.

Download

Manual

Download

Manual Video

Video

Connect:

Connect: