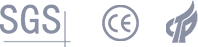

Precision Engineering for Maximum Productivity

REHOBOTH pelletizing machines represent decades of manufacturing expertise, featuring robust 38CrMoAl nitride-treated screws and heavy-duty gearboxes that deliver continuous operation with minimal maintenance. Our triple-stage systems process 2-5 tons/hour of recycled materials, transforming waste plastic into uniform pellets ready for premium manufacturing applications.

Energy-Efficient Performance

-

Advanced Heating System: Electromagnetic heating technology reduces power consumption by 35% compared to conventional resistance heaters

-

Smart Motor Control: 6-pole motors with frequency conversion ensure optimal power usage across varying loads

-

Thermal Management: Precision temperature control (±2°C) maintains material properties while reducing energy waste

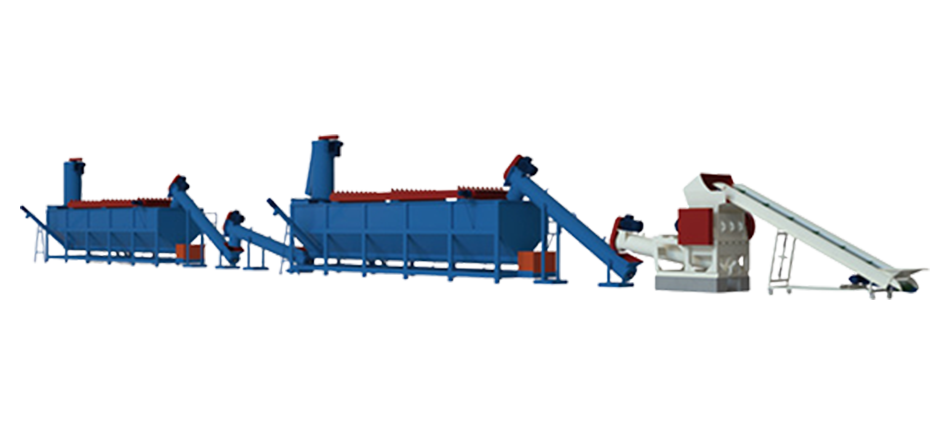

Proven Applications

Our systems successfully process:

-

PET flakes from bottle recycling

-

PP/PE films and woven bags

-

Engineering plastics (ABS, PC)

-

Industrial plastic scrap

Technical Specifications

| Model | Gearbox | Screw Size | Motor Power | Capacity |

|---|---|---|---|---|

| Main Machine | 330 Hard Gear | 220×3500mm | 90KW | 1500kg/h |

| Secondary | 280 Hard Gear | 180×1800mm | 37KW | 800kg/h |

| Tertiary | 280 Hard Gear | 155×1600mm | 30KW | 500kg/h |

Why Industry Leaders Choose REHOBOTH

"After switching to REHOBOTH equipment, our production efficiency increased by 40% while energy costs decreased by one-third. The robust construction has significantly reduced our maintenance downtime." - Manufacturing Director, Vietnam Recycling Plant

Comprehensive Service Commitment

-

12-month warranty on all components

-

Lifetime technical support

-

72-hour emergency response

-

Regular maintenance reminders

Download

Manual

Download

Manual Video

Video

Connect:

Connect: