Technological Breakthrough

Its core "underwater pelletizing module" uses precisely temperature-controlled circulating water to cut molten polymer into uniform pellets the moment it exits the die, achieving an astonishing processing capacity of up to 22 tons per hour. Compared to traditional equipment, this system reduces energy consumption by 40% while increasing product purity to 99.2%, truly transforming waste plastic from "waste" to "golden raw material."

Energy Efficiency Revolution

REHOBOTH's “Dual-Stage Energy-Saving System” is driving disruptive innovation:

- Electromagnetic Heating Technology: Directly acts on the material pipe for heating, improving thermal energy utilization by 70%

- Intelligent Frequency Conversion Control: Automatically adjusts motor power according to load, avoiding energy waste

- Heat Recovery Device: Captures waste heat generated during the pelletizing process, enabling energy recycling

In the practical application of a large-scale recycled plastic enterprise in Zhejiang, this system saves more than 1.8 million yuan in electricity costs annually, recovering the entire renovation investment in just 14 months.

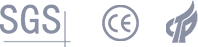

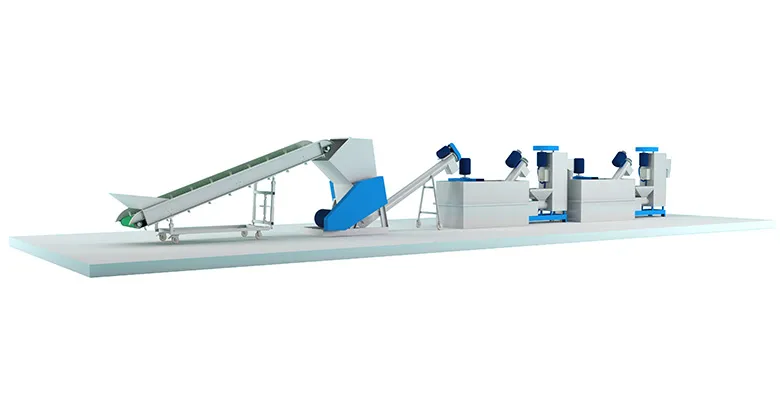

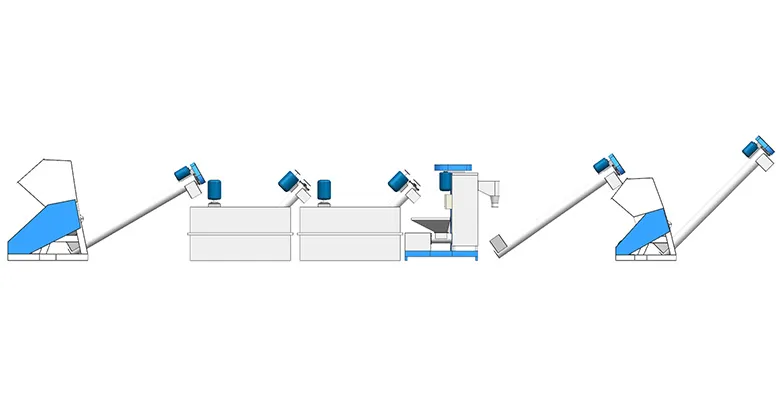

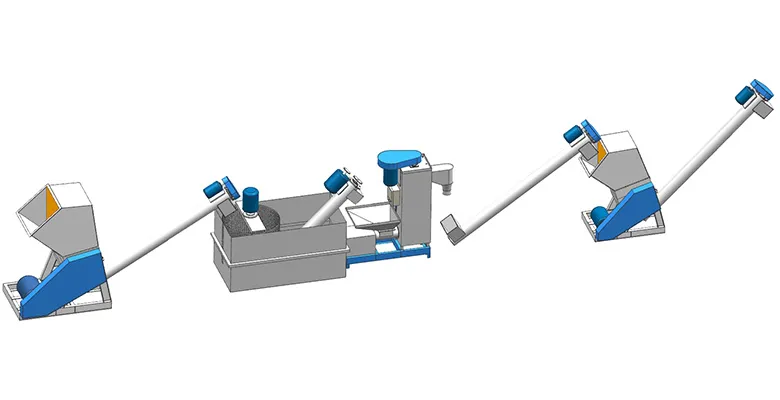

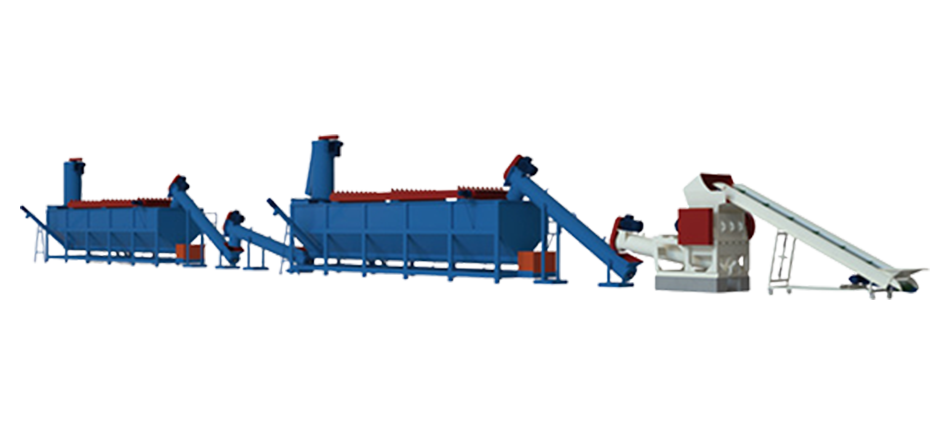

Efficiency of Fully Automated Production

Our cleaning and pelletizing production line integrates an advanced intelligent control system, achieving full-process automation from feeding to finished product:

The system's 60 cubic meter wastewater treatment device achieves 95% water resource recycling, completely solving the pollution problem in the plastic cleaning industry. In a demonstration factory in Jiangsu, the entire production line requires only 3 operators but achieves the output of a traditional line with 20 people.

Grade Materials for Long-Lasting Durability

To ensure stable equipment operation in harsh environments,REHOBOTH spares no expense on key components:

-

Screw and Barrel: Use high-strength 38CrMoAl alloy steel, with a service life exceeding 8,000 hours

-

Transmission System: Hardened gearbox through carburizing and quenching, increasing load capacity by 50%

-

Structural Frame: Welded with 20mm medium carbon steel plate, passing 1 million fatigue tests

The application of these military-grade materials enables the equipment to maintain performance even in high-temperature and high-humidity environments in Southeast Asia, reducing failure rates by 65% compared to the industry average.

Co-creating a Sustainable Tomorrow

When REHOBOTH 's cleaning and pelletizing systems operate stably in every corner of the world, when waste plastic bottles undergo a magical transformation into high-quality recycled pellets, what we see is not only the success of individual equipment but also a beautiful future of harmonious coexistence between humanity and nature.

Download

Manual

Download

Manual Video

Video

Connect:

Connect: