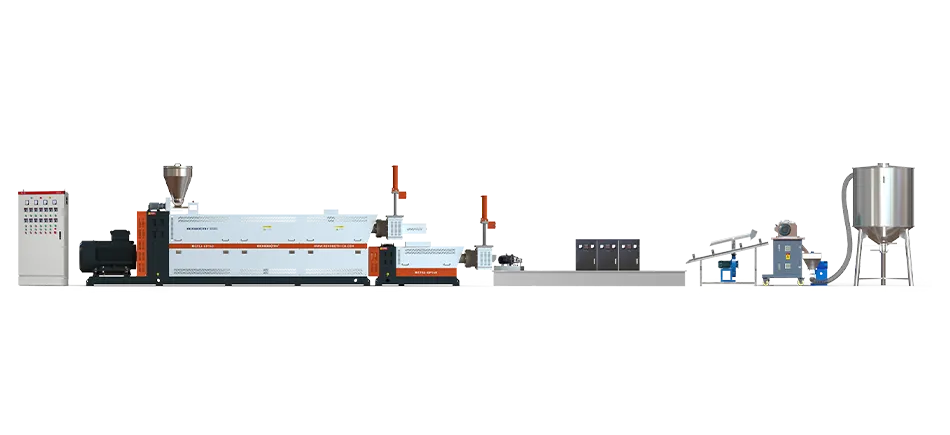

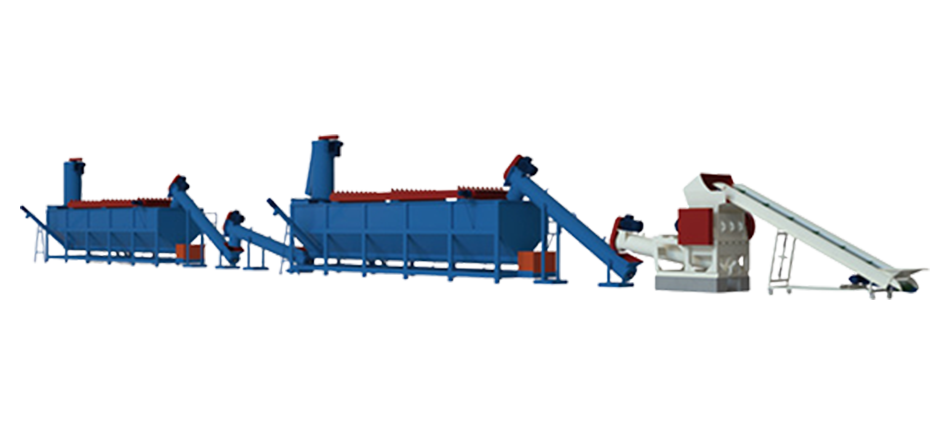

Imagine your yard is piled high with broken HDPE bottles, tangled PP plastic crates, and rigid ABS scraps. They've been shredded, but what's next? The real bottleneck—the point that determines whether these fragments become marketable goods or simply take up more space—lies in granulation. You need more than just a machine; you need a reliable rigid plastic recycling granulator that can consistently transform this messy waste into uniform, dense pellets, ready for the extruder next door or the market further afield. The answer isn't a standalone piece of equipment, but a seamlessly integrated waste plastic recycling and granulation system.

Why Your Recycling Line Depends on Granulator Performance

Let’s cut through the industry jargon. Having a powerful shredder is like having a great chef who only chops vegetables. Without a proper stove (the pelletizing machine), you’ll never serve a meal. In the plastic waste management ecosystem, the pelletizer is that critical cooking appliance. It’s the component that adds tangible, market-defining value. Flakes are vulnerable—they can contaminate, have inconsistent bulk density causing feeding issues, and degrade if stored poorly. Pellets, born from a stable granulation process, are the gold standard. They flow like grain, blend uniformly for precise recipes in new products, and command a premium price.

Vibration, frequent screen changes, inconsistent melt temperatures, and “angel hair” formations weren’t just nuisances; they were profit leaks. A 2022 report by the Association of Plastic Recyclers highlighted that nearly 30% of potential throughput in mid-sized recycling plants is lost due to downstream bottlenecks, with pelletizing being a primary culprit. This isn’t a minor technical detail; it’s the core of your plastic reutilization business model.

What Makes a Rigid Plastic Granulator "Industrial Grade"?

So, what separates a cost-center machine from a profit-generating workhorse? It’s a blend of brutal strength and precise control. For rigid plastics like HDPE, PP, and ABS, the system must be a fortress.

First, the heart: the granulator cutter hub. Forget thin, stamped blades. REHOBOTH employs forged, heat-treated rotors with staggered, helical configurations. This isn’t just about cutting; it’s about shearing and pulling material through with a constant, smooth force. The result? Lower amperage spikes, reduced noise (a tangible workplace benefit), and a dramatically extended blade life. I’ve seen our rotors in facilities processing over 5,000 metric tons before a first major service, a testament to this “over-engineering” philosophy.

Second, thermal management. Rigid plastic recycling generates heat through friction. An inferior system lets this heat run wild, causing premature degradation—a “cooked” look and weakened polymer chains. Our recycling pelletizing line integrates a closed-loop, multi-zone temperature control. It doesn’t just cool; it manages, ensuring the melt is homogenous before it’s strand-extruded and cut. This precision is what yields those crystal-clear, bubble-free pellets your buyers want.

Finally, the often-overlooked hero: the die face and cutting chamber. Quick-change screen packs are a given. But we focus on the cutter geometry and chamber evacuation. By optimizing airflow and knife angles, we virtually eliminate the dreaded “fines” (dust) and “tails” that plague output quality. What you get is a clean, uniform plastic regrind ready for the next life.

Beyond the Machine, Achieving System Synergy

Anyone can sell you a pelletizer. REHOBOTH engineers a granulation ecosystem. This distinction is everything. Our pelletizing system starts with understanding your specific feedstock cocktail. Is it 80% HDPE bottles with 20% PP caps? Or is it a stream of post-industrial ABS with paint labels? Each blend behaves differently.

We then model the entire process flow. For instance, we might recommend a dedicated pre-drying hopper for certain materials before they even enter our high-capacity pelletizer, preventing steam vents and ensuring pellet integrity. Our downstream pellet cooling and classifying systems are tuned to match the pelletizer output, creating a seamless handoff that maximizes throughput. This holistic view is our secret sauce. It’s the difference between buying a tool and adopting a solution.

Our field technicians, who I’ve spent countless hours with on client sites, share a common observation: the biggest gains come from matching the entire line’s tempo. A REHOBOTH system is conducted like a symphony, not a series of solo acts. This synergy reduces energy consumption per kilo by up to 15% compared to mismatched components—a saving that goes straight to your bottom line.

A Detailed Case Study

Let’s get practical. Imagine a client, “EcoPoly,” processing post-consumer agricultural PP bins—dirty, sun-degraded, and often mixed with rubber seals. Their old setup produced weak, foamy pellets full of impurities.

We deployed our R-Force 5000 rigid plastic recycling pelletizer as part of a tailored system. The process:

-

Pre-conditioning: A REHOBOTH friction-washer (not part of every system, but critical here) removed abrasive contaminants before size reduction.

-

Feeding & Melting: A twin-screw extruder segment, integrated with the pelletizer, provided aggressive yet controlled melting, handling the degraded polymer’s variable viscosity.

-

Filtration & Pelletizing: A massive, automatic screen changer caught the remaining micro-contaminants. Then, the pristine melt hit our granulator unit. The key here was the large, water-ring cutting chamber, which instantly quenched the hot-cut pellets, preventing clumping.

-

Final Classification: A centrifugal dryer and vibrating sieve ensured only perfect, 3mm PP pellets were bagged.

The outcome wasn’t just a machine installation. It was a product transformation. EcoPoly’s pellets went from a discounted filler material to a premium-grade feedstock for new bin manufacturers. Their plastic reutilization story became a marketing asset.

Customization and Scalability

The recycling landscape isn’t static. Tomorrow’s waste stream will be different. Locking yourself into a rigid, one-size-fits-all plastic recycling machine is a strategic risk. My perspective, forged from two decades in this field, is that flexibility is the new durability.

REHOBOTH builds this in. Our waste plastic recycling and granulation system platforms are modular. Need to add a third filtration stage for a new client’s super-clean spec? It’s a bolt-on upgrade. Planning to expand capacity by 40% next year? Our drive trains and frame designs are pre-engineered for it. We offer control software that not only monitors but learns, optimizing cut length and temperature based on real-time feedback.

This isn’t just about hardware. It’s about partnering with a team that sees your future challenges. When you talk to our engineers, you’re not getting a sales pitch for Machine Model X. You’re starting a conversation that begins with, “What are you trying to build, and what might come your way next?” That’s how you build a resilient business, not just a processing line.

Conclusion

The journey from a yard full of fragmented plastic to a silo full of premium pellets is a technical one, but it doesn’t have to be a leap of faith. It starts with clarity about your own operation’s unique fingerprint—your feedstock, your pain points, your ambition.

REHOBOTH is here to map that journey with you. We don’t believe in off-the-shelf miracles. We believe in engineered, collaborative solutions that make your waste plastic recycling and granulation system the most reliable, profitable part of your enterprise.

Ready to transform your plastic waste stream into a consistent revenue stream? Contact our engineering team today for a no-obligation, site-specific analysis. [Visit our Granulation Systems Page to start the conversation].

Download

Manual

Download

Manual Video

Video

Connect:

Connect: