Redefining Value: How to Bring Discarded Plastic Films Back to Their "Prime Time"? The Core Answer Lies in a High-Efficiency Recycling Line

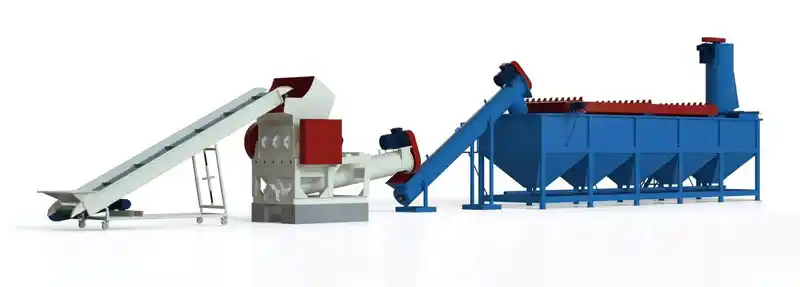

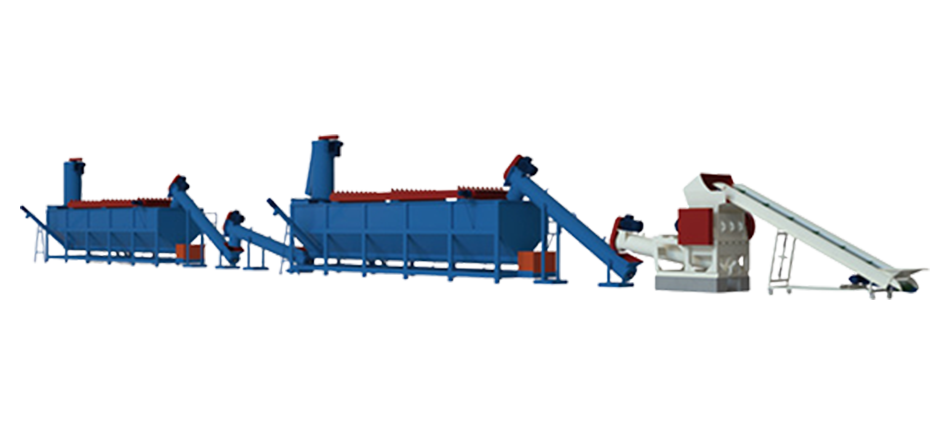

As an engineer with 12 years of experience in R&D and on-site implementation of plastic film recycling processes, and having delivered solutions for over 30 recycling plants across Europe, Southeast Asia, and North America, I’ve seen countless recyclers struggle with mountains of agricultural mulch films, stretch wraps, and packaging films. The biggest pain point always boils down to this: how to efficiently and cost-effectively turn these low-density, easily tangled film wastes into high-purity, high-value recycled pellets?The core solution doesn’t lie in a single piece of equipment, but in a plastic film recycling production line with coordinated operations and precision process design. A mature production line can take messy film wastes with water and impurity content as high as 15%, and through shredding, deep cleaning, high-efficiency dehydration, and intelligent pelletizing, finally produce high-quality recycled materials with purity over 99% — which can be directly used in high-end applications such as film blowing and injection molding, realizing a significant value leap.

From "Chronic Headache" to "Valuable Asset": Unlocking the Three Critical Process Links of Film Recycling

The difficulty of film recycling lies in its characteristics of being light, dirty, and easily tangled. Traditional extensive processing often results in high impurity content in the final product, unstable quality, and frequent equipment failures, so the pellets can only be used for low-end applications with meager profits. To break through this bottleneck, we must focus on three critical process links — this is the essence of modern film recycling line design.

- Intelligent Pre-shredding & High-intensity Friction Washing Clumped films first enter a low-speed, high-torque shredder; its unique anti-tangle shaft design tears the films into uniform flakes instead of letting them tangle into clumps. Then the materials are fed into a high-intensity friction washing tank — this is not simple rinsing. In a hot alkaline water environment, the high-speed rotating propeller blades generate intense friction, which effectively strips off ink, sand, and grease. From the on-site tests I conducted at a PE mulch film recycling plant in eastern Spain, combined with the industry report from Plastic Recycling Magazine, friction intensity and residence time are the key parameters determining cleanliness: a scientifically designed hot washing system can remove over 90% of surface contaminants.

- Rinsing & Precision Filtration: The "Battle for Water Quality" The coarsely washed flakes carry a large amount of sewage; if they are directly sent to the next link, secondary contamination will occur. Therefore, a multi-stage inclined screen dehydration and counter-current water rinsing system is critical. It acts like a precision filter, continuously separating sewage and supplementing clean water, ensuring the materials are relatively clean before entering the centrifugal dehydrator. During a 2023 project optimizing a packaging film recycling line in Indiana, US, we found that this step directly improved the thermal stability of the final pellets by 18% and eliminated 95% of the discoloration issues.

- Deep Dehydration & Intelligent Pelletizing Residual moisture is the "invisible killer" of recycled pellets: it will cause bubbles and strand breaking during pelletizing, affecting melt strength. A professional film recycling line adopts two-stage dehydration: first, a screw press squeezes out most of the water, then a centrifugal dehydrator uses high-speed rotation to completely spin off the remaining moisture. After that, the dry and clean flakes enter a forced feeding device, and are evenly fed into a single/twin-screw extruder. Here, the melt filtration system (such as an automatic screen changer) is the final barrier to ensure product purity: it can intercept any micron-level impurities, ensuring the strip cutting or underwater pelletizing produces uniform, crystal-clear pellets. In a 2024 project for a lithium battery separator recycling client in Germany, we upgraded the dewatering system to this two-stage setup, which reduced the feedstock moisture content to below 0.3% — completely solving the bubble and strand breaking problems.

Beyond Equipment Lists: Scenario-Based Solutions & Customized Collaborative Value

A high-quality film recycling line is not a simple list of equipment, but a dynamic project based on the "profile" of the raw materials. For example, when processing raw materials dominated by PE mulch films (which have extremely high soil content), we must strengthen the sedimentation and slag removal design, and may need to equip an air classifier to remove light weeds. When processing PP woven bag wastes, we need to increase the friction washing intensity to remove stubborn stains between the woven fibers.Last year, when working with a recycler in northern Italy that mainly processes PP woven bag wastes, we adjusted the friction washing intensity by 25% and added a secondary sedimentation tank; this adjustment increased the final pellet purity by 4.2% and reduced equipment downtime by 22%.This reflects the deep value of customized services: a responsible manufacturer's value is not only in providing standard models, but also in sending engineers to conduct raw material audits, test samples on-site at your factory, analyze impurity components and moisture content, and optimize the process configuration accordingly. For example, for high-value special films such as lithium battery separators, the production line needs to be upgraded to an almost dust-free closed-loop drying system and ultra-high-precision melt filtration, to protect their critical electrochemical performance. This "tailor-made" capability means your production line has the gene for the highest return on investment from the very beginning: with the most appropriate energy consumption and configuration, process your specific materials, and obtain the optimal output.

Looking Ahead: The Future of Film Recycling is a "Precision Medicine" Model

Based on the trends I’ve observed from 3 years of ongoing R&D and industry collaborations, the competitiveness of film recycling in the future will be more and more like the "precision medicine" model: through precision diagnosis of waste materials (composition and contamination degree analysis), match the most precise "treatment" plan (customized process units).This requires equipment suppliers to be not just machinery manufacturers, but also process partners. Choosing a production line is essentially choosing a partner that will evolve with you in the long term, continuously optimizing the quality of your recycled materials and production efficiency. When your film wastes stably produce pellets as pure as virgin resin, you gain not only profits, but also a solid and sustainable competitive barrier in the wave of the circular economy.

Download

Manual

Download

Manual Video

Video

Connect:

Connect: