Choosing the right plastic granulation line series directly determines production efficiency, product quality, operating costs, and long-term profitability. There is no "one-size-fits-all optimal" series; the core is to match your actual needs—including the type of plastic to be processed, production scale, finished product requirements, budget constraints, and automation needs. Below, combined with the practical characteristics of mainstream granulation line series, we provide professional selection guidelines to help you make an accurate decision.

1. Key Criteria for Selecting a Plastic Granulation Line

Before delving into specific series, clarifying core needs is the foundation of selection. It is recommended to sort out from the following dimensions:

-

Processed Materials: Are they common general-purpose materials (PE, PP), engineering plastics (ABS, PC, PA), recycled materials (agricultural film, packaging film, plastic bottles), or filled/reinforced composite materials? Different materials have significant differences in melting characteristics, impurity content, and temperature resistance, which directly determine equipment compatibility.

-

Production Scale: What is the expected hourly output? Small-scale production (below 100kg/h), medium-scale (100-500kg/h), or large-scale (above 500kg/h)? Production capacity directly matches equipment specifications and series selection.

-

Finished Product Quality Requirements: Is high-purity, uniform particle size required? Is particle shape (cylindrical, spherical) critical for subsequent processing (such as injection molding, extrusion)?

-

Budget and Operating Costs: What is the initial investment budget range? Is it necessary to prioritize energy-saving, consumption-reducing, and low-maintenance-cost equipment?

-

Automation Needs: Can manual intervention (such as threading strands during startup) be accepted, or is fully automated operation required to reduce labor costs?

-

Workshop Conditions: Is the workshop space limited? Are there strict environmental requirements (such as low dust, low noise)?

2. Mainstream Plastic Granulation Line Series & Their Suitability

Currently, mainstream granulation line series on the market can be divided into three categories according to pelletizing methods: Strand Pelletizing Lines, Water Ring Pelletizing Lines, and Underwater Pelletizing Lines. In the recycled plastic field, the Double-Stage Strand Pelletizing Line series, specially designed for high-impurity materials, is also highly favored and is a mainstream special solution in the industry.

2.1 Strand Pelletizing Line Series

Strand pelletizing is a mature and widely used process. The core process is: molten plastic is extruded through a multi-hole die to form strands, cooled by a water bath or water slide, dried, and then cut into cylindrical particles by a pelletizer. Specifically, it can be divided into two sub-series: dry cutting and wet cutting (water slide). From a practical perspective, this process has a wide range of applicable scenarios and is the basic selection for small and medium-scale production capacity.

Core Advantages (Practical Level)

-

Low initial investment and high cost performance, making it the preferred solution for small and medium-sized enterprises (SMEs) with limited budgets.

-

Extremely strong material compatibility: Suitable for most plastics such as PE, PP, ABS, PC, and PET, and can even handle some filled composite materials. It is especially suitable for contract manufacturing enterprises that need frequent material changes—material change and cleaning are convenient, and downtime losses are small.

-

Simple operation and maintenance: The equipment structure is intuitive, core components are easy to disassemble, and the threshold for daily cleaning, color changing, and maintenance is low, requiring no professional operation and maintenance team.

-

Flexible configuration: The water slide sub-series can replace the traditional water bath, which not only reduces cutter wear but also improves the degree of automation and reduces the need for manual intervention.

Practical Limitations

-

High labor intensity: Manual strand threading is required during startup, and special personnel are also needed to inspect the stability of strands during continuous production, making it unsuitable for fully automated production lines.

-

Limited particle shape: Cylindrical particles have flat end faces and are prone to agglomeration; if small particle size is required, strands are easy to break, resulting in low finished product qualification rate.

-

Large floor space: The water bath device requires additional space, which is not friendly to small workshops.

-

Dust and wear issues: Cutting solidified strands generates a lot of dust, and the cutter wears quickly, requiring frequent replacement and increasing consumable costs.

Suitable Scenarios

SMEs, contract manufacturing enterprises, or scenarios with production capacity below 500kg/h that need to take into account the processing of multiple types of plastics; enterprises with limited budgets and acceptable moderate manual intervention can also give priority to selection. Practical case: The JSG Automatic Dry Cut Strand Pelletizing System from MAAG Group, with high-end configuration, can meet the production of high-end composite materials at 9000kg/h, while the basic model is fully suitable for small-scale recycled material processing with outstanding cost performance.

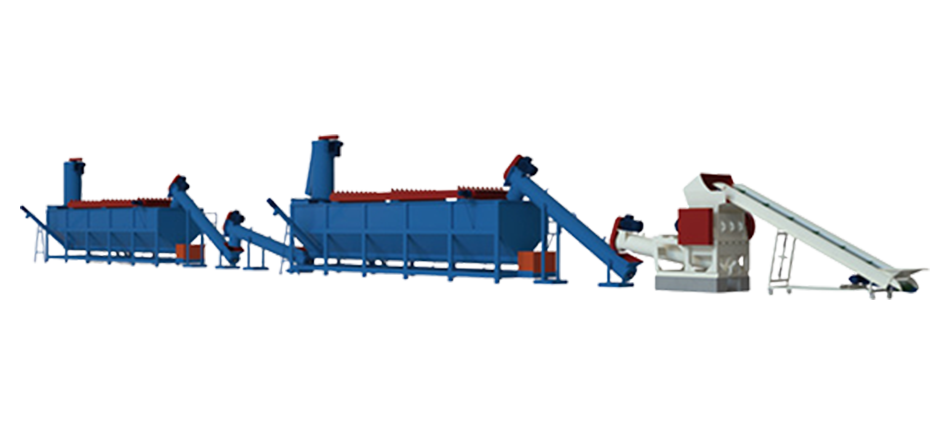

2.2 Water Ring Pelletizing Line Series

Water ring pelletizing belongs to the die-face pelletizing process. The core process is: molten plastic is extruded through an annular die, directly cut into oblate particles by rotating cutters on the die face, and at the same time, particle cooling and transportation are realized through a circulating water ring. This process is widely used in PE and PP processing, especially suitable for medium-scale recycled material production lines.

Core Advantages (Practical Level)

-

Compact structure: No separate water bath device is needed, and the floor space is only 60%-70% of that of strand pelletizing lines, making it particularly suitable for workshops with limited space.

-

Balanced investment cost performance: The initial investment is lower than that of underwater pelletizing lines, and it takes into account both production capacity and quality, making it the "transitional preferred choice" for medium-scale enterprises.

-

High operational stability: Strong tolerance to fluctuations in melt temperature and pressure, no die freezing risk; one-key start and stop, operable by a single person, greatly reducing labor dependence.

-

Low noise and stable quality: Uniform cooling by the water ring ensures good consistency of particle size; the closed pelletizing environment has less dust and low noise, meeting basic environmental protection requirements.

Practical Limitations

-

Narrow material adaptability: Only suitable for high melt strength plastics such as PE and PP, and has poor adaptability to high-temperature, high-viscosity engineering plastics (such as ABS, PC), which are prone to cutter sticking and particle deformation.

-

Low production capacity ceiling: The maximum production capacity is usually no more than 5000kg/h, which cannot meet the needs of large-scale production.

-

Limited particle shape adaptability: Oblate particles have poor fluidity and cannot meet the downstream processes that require high particle fluidity such as injection molding and precision extrusion.

Suitable Scenarios

Medium-scale enterprises focusing on processing PE, PP, and PS as core materials, especially suitable for the recycled plastic field (such as agricultural film and packaging film recycling); scenarios with limited workshop space, moderate budget, and requiring stable operation and low manual intervention are preferred. From the perspective of industry applications, this series is the mainstream configuration for medium-scale production lines of PE/PP recycled materials.

2.3 Underwater Pelletizing Line Series (UWP)

Underwater pelletizing is the most advanced die-face pelletizing technology currently. Its core advantage lies in "instant cooling + precise pelletizing": the pelletizing chamber is fully filled with circulating water, and molten plastic is cut into spherical particles by underwater rotating cutters immediately after being extruded from the die holes, and then cooled, transported, and dried through water circulation. This process is the core choice for high-end and large-scale production.

Core Advantages (Practical Level)

-

Top-tier finished product quality: Spherical particles have excellent fluidity and high bulk density, which can significantly improve the processing stability of downstream injection molding and extrusion, and are an essential raw material guarantee for high-end products (such as auto parts and electronic casings).

-

Large production capacity scale: Designed for large-scale production, the maximum production capacity can reach 35000kg/h (77000 pounds/hour), far exceeding strand and water ring pelletizing lines, suitable for large-scale intensive production.

-

High degree of automation: Full PLC closed-loop control, with functions such as automatic cutter adjustment, online die grinding, and quick start and stop, short downtime, and labor costs can be reduced by more than 60%.

-

Full material adaptability: Can handle almost all types of plastics, including engineering plastics such as ABS and PC, filled composite materials, and high-requirement recycled materials, especially suitable for the production of masterbatches and functional masterbatches.

Practical Limitations

-

High initial investment: It is the most costly among the three mainstream series, and the initial equipment investment is 3-5 times that of strand pelletizing lines, requiring strong financial strength.

-

High operation and maintenance threshold: A professional team is required to manage the water circulation temperature control and filtration system, and equipment commissioning and troubleshooting require rich experience, which is difficult for SMEs to operate and maintain independently.

-

High operating costs: The water circulation treatment system consumes a lot of energy, and filter consumables need to be replaced regularly, resulting in higher long-term operating costs than other series.

Suitable Scenarios

Large-scale production enterprises, high-end composite material factories, or manufacturers of masterbatches, engineering plastics, and high-value-added products; enterprises with sufficient budgets that pursue high efficiency, high quality, and fully automated production are preferred. Typical application: In the field of automotive plastic parts and electronic product casing production, where high requirements are placed on particle quality and production capacity stability, underwater pelletizing lines are the core configuration.

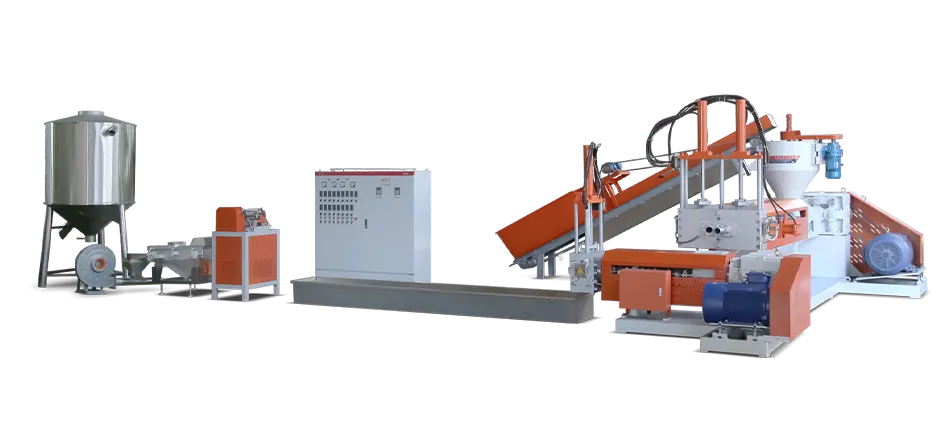

2.4 Double-Stage Strand Pelletizing Line Series (for Recycled Plastics)

This series is a special upgraded version of strand pelletizing lines, specially designed for high-impurity recycled materials (such as agricultural film, woven bags, and waste plastic bottles). It adopts a "main extrusion + secondary plasticization" double-stage mother-son machine structure, combined with multi-layer filtration and sufficient devolatilization systems, to accurately solve the industry pain points of uneven plasticization and easy coking of high-impurity materials.

Core Advantages (Special for Recycled Materials)

-

Strong impurity handling capacity: The first-stage main machine is responsible for preliminary melting and coarse filtration, and the second-stage sub-machine realizes deep homogenization, devolatilization, and fine filtration, which can effectively remove sediment, fibers, and other impurities in recycled materials, and solve the core problems of uneven plasticization and coking of high-impurity materials.

-

Flexible material adaptability: Can directly process dry or wet materials without additional drying procedures, saving more than 30% energy compared with traditional equipment and greatly reducing energy consumption costs.

-

Stable production capacity and low loss: The finished particles are dense and smooth, and the material loss rate is controlled within 5%, which is much lower than that of traditional single-stage equipment, improving raw material utilization rate.

-

Significant energy-saving effect: The unit energy consumption is 15-20% lower than the industry average, with obvious long-term operating cost advantages.

-

Comprehensive operation and maintenance support: Most manufacturers (such as Saiwang Technology) provide turnkey projects, covering the entire process of installation, commissioning, and operator training, reducing the operation and maintenance threshold for recycling enterprises.

Suitable Scenarios

Recycled plastic enterprises of all scales, especially those processing low-grade, high-impurity recycled materials. Practical case: The PE/PP Double-Stage Strand Pelletizing Line (model SWS130-28/SWS130-10) from Saiwang Technology has a production capacity of 250-300kg/h, which is perfectly suitable for small and medium-sized recycling plants; at the same time, it supports production capacity expansion and can meet the large-scale production needs of large recycling centers.

3. Quick Selection Checklist

The following quick selection checklist can help you quickly lock in the suitable series and improve selection efficiency:

-

Processing high-impurity recycled materials: Prioritize Double-Stage Strand Pelletizing Lines to accurately solve impurity handling and uneven plasticization problems;

-

Small-medium production capacity (<=500kg/h), need to take into account multi-material processing, limited budget: Prioritize Strand Pelletizing Lines for optimal cost performance and adaptability;

-

Medium production capacity (100-5000kg/h), core processing of PE/PP, limited workshop space: Prioritize Water Ring Pelletizing Lines to balance production capacity and space needs;

-

Large-scale production capacity (>=500kg/h), pursuit of high-end finished product quality, sufficient budget: Prioritize Underwater Pelletizing Lines to match high-value-added production needs;

-

Downstream requires high-fluidity particles (such as precision injection molding): Directly select Underwater Pelletizing Lines; if the budget is limited, consider Strand Pelletizing Lines with supporting particle shaping equipment.

Download

Manual

Download

Manual Video

Video

Connect:

Connect: