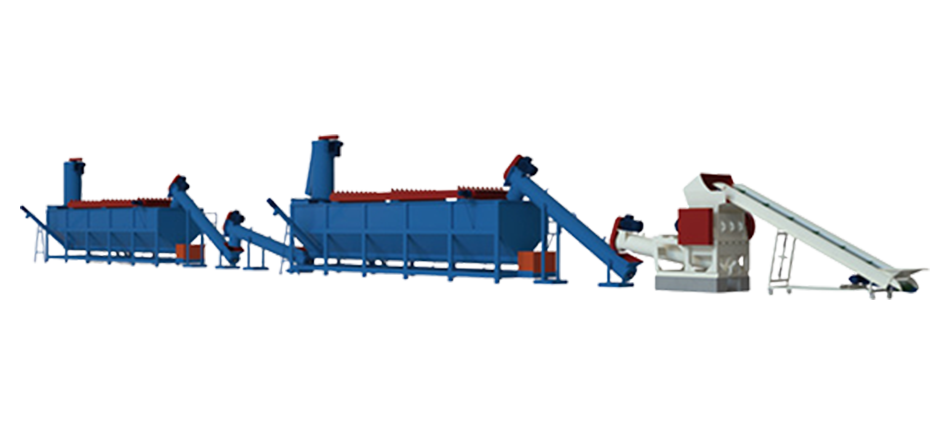

In reducing the costs of PET plastic recycling and washing lines, the key lies in three practical areas: improving energy and water recycling efficiency, increasing material utilization through targeted process improvements, and significantly reducing long-term operating costs through intelligently customized equipment configurations. According to the "2023 China Renewable Resources Recycling Industry Development Report" I reviewed, companies adopting advanced recycling systems can reduce unit processing costs by 30% to 45% – and REHOBOTH has helped dozens of clients achieve this goal through its tailored PET recycling solutions. For most recycling companies, whose profit margins are already thin due to fluctuating crude oil prices, these cost-saving measures are not just technological upgrades, but crucial for survival and growth in a highly competitive market.

Let's start with the most obvious operating costs: water and electricity. A medium-sized recycling plant in East China previously consumed 8 to 10 cubic meters of water per ton of PET bottles processed, with electricity costs alone accounting for 28% of its monthly operating costs. After upgrading to REHOBOTH's closed-loop water recycling system, the results were dramatic: water consumption dropped to just 1.2 cubic meters per ton, a significant reduction of 85%. This is because the system uses multi-stage filtration to progressively recycle the washing water. Combined with energy-efficient motors and heat recovery devices, their electricity costs decreased by another 32%. The factory manager frankly told me, "We save nearly $12,000 in utility costs every month – money that used to pay the salaries of three workers." For small and medium-sized enterprises facing cost pressures, this is not just a number on a spreadsheet, but real breathing room.

Material waste is another hidden cost that many recycling companies have come to accept as inevitable. Many believe that losing 5% to 8% of raw materials during the crushing and washing process is unavoidable, but this is not the case. REHOBOTH's modular PET washing line is designed to address this problem, allowing for flexible combinations of different process flows based on your needs. For example, one of their Indonesian clients uses the system to process mixed-color PET bottles to produce food-grade PET flakes. REHOBOTH added a Z-type precision sorting system to sort out tiny PVC impurities that are almost invisible to the naked eye, and improved the V-shaped rotor of the crusher to reduce powder loss. The result? Their material utilization rate increased from 92% to 98.5%, and the market price of high-purity PET flakes increased by 15%. The truly ingenious aspect is their on-site waste recycling module – which converts small fragments that were previously discarded into usable materials. This detail fully demonstrates the brand's deep understanding of the daily operations of recycling.

Long-term operational stability is crucial for cost control – one day of unplanned downtime can wipe out a month's profit. Real-time monitoring features alert operators to potential problems 2 to 3 hours in advance, allowing for repairs before a breakdown occurs, rather than scrambling to fix it afterward. "Stability alone saves us over $50,000 in downtime losses annually," he said. This reliability is not accidental – it stems from REHOBOTH's use of wear-resistant materials and continuous design improvements based on over 20 years of industry experience.

Customization is key to maximizing these cost savings – there is no "one-size-fits-all" solution in PET recycling. REHOBOTH redesigned the layout of their integrated PET production line, reducing its footprint by 20% while maintaining a capacity of 1000 kg per hour. For customers using low-purity raw materials, they add an extra pre-sorting module to prevent clogging and ensure smooth operation. This is the advantage of customized service: it ensures you get the most return on every dollar spent on equipment, rather than forcing you to remodel your entire factory to fit a rigid, single system.

Currently, the recycled PET market is growing at 7.2% annually, but profit margins are shrinking. This means that cost control is no longer simply about cutting expenses, but about making smart upgrades. REHOBOTH's PET plastic recycling and washing lines stand out not only for their advanced technology but also for their ability to translate this technology into tangible, reliable cost savings. From reducing utility bills and minimizing material waste to improving operational stability and providing solutions perfectly tailored to your needs, every aspect is designed to help recycling businesses increase profitability. Turn cost pressure into an advantage.

If you want to succeed in the circular economy, choosing the right partner and equipment is not just a choice, but the first step in ensuring the long-term profitability of your business. If you need anything, please click on REHOBOTH's contact page!

Download

Manual

Download

Manual Video

Video

Connect:

Connect: