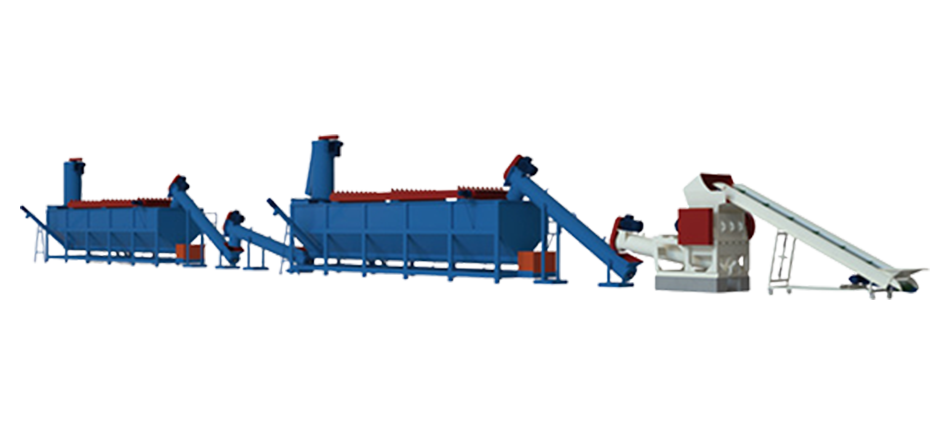

When the last dewatering machine equipped with stainless steel screens completed its rust-proof packaging, the REHOBOTH technical team signed the packing list—marking another plastic recycling system ready to cross the Indian Ocean to a recycling plant in Tanzania. In the roar of the container, we witness not just the voyage of equipment, but a transnational relay of the circular economy.

On-Site Testing: Precision Gamble Where Data Speaks

At the critical stage before shipment, REHOBOTH insists on executing the standard process of On-Site Machine Testing. Representatives from Tanzania personally fed oil-stained PET flakes into the Integrated Crusher & Washer, watching the unit complete the entire process of "crushing - pre-washing - rinsing" within 15 minutes, finally producing clean flakes with a moisture content below 2%. This "seeing is believing" verification method is our sharp tool for breaking down trust barriers in international trade.

Live Testing Data Record:

-

Uniform fragmentation rate ≥95%

-

Residual impurity ratio ≤0.3%

-

Water and electricity cost per ton reduced by 42%

The Precision Layout of a Professional R&D Team

In the REHOBOTH laboratory, the Professional R&D Team is simulating the high-temperature and high-humidity environment of East Africa. To adapt to Tanzanian climate characteristics, we have implemented three upgrades to the corrosion-resistant Dewatering Machine:

-

Screen material upgraded to 316L stainless steel

-

Control system added voltage fluctuation compensation module

Tailored Recycling Solutions

Addressing Tanzania's current power instability, REHOBOTH innovatively launched a "Grid-Friendly" design scheme:

-

The Integrated Crusher & Washer uses soft-start technology to cope with sudden voltage changes

-

The Dewatering Machine features dual-mode switching (mains/generator)

-

The Pelletizer's heating unit is equipped with smart peak/valley electricity usage modules

Local customers praise: "These machines seem born for Africa, running stable even with 3 power outages a day."

Value Extension: From Equipment Supplier to Industrial Partner

We deliver not just machinery, but a circular economy ecosystem containing:

- Bilingual training manuals for local operators

- Spare parts pre-positioning plan (common parts shipped with the host machine)

- Remote diagnostic system (supporting real-time WhatsApp video guidance)

- Quarterly process optimization reports (providing continuous production improvement solutions)

Towards the Future

As REHOBOTH equipment starts operating at the foot of Mount Kilimanjaro, the 3 tons of plastic waste processed per hour by each Integrated Crusher & Washer is rewriting the narrative of plastic pollution in East Africa. We invite global partners to witness together: under the dual guarantees of professional R&D and full-process control, the revolutionary fire of green manufacturing is spreading across the African continent.

Download

Manual

Download

Manual Video

Video

Connect:

Connect: